In the present global crisis, Sinclair & Rush are keen to play their part in supporting the globe to defeat COVID-19. In a special move for the company, Friday 27th March saw a pitch to the company owners for a face shield to support the lack of PPE in the health industry. In just 1 week, the 'VisiGuard' face shield was born and released to the public.

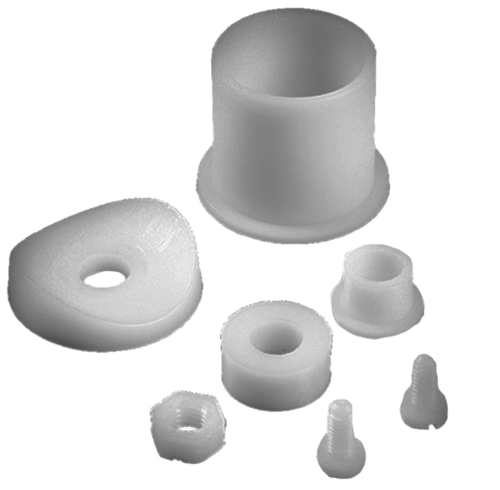

The VisiGuard comprises of completely recyclable PET that is resistant to Isopropyl Alcohol, Hydrogen Peroxide or bleach which are cleaning agents commonly found in medical environments. Furthermore, there is no foam or other unsanitary materials involved in the production which eliminates the chance of contaminating the mask.

All of our Face Shields are manufactured in a cleanroom ensuring that they arrive with you in a sanitary and ready-to-use condition. See the video below for an example from our US Production facility showing the precautions we take when manufacturing medical-grade products.

The simple design requires only seconds of minimal labour, attaching the strap to the plastic shield, and comes with instructions if needed. The shields pack densely, minimizing storage space and transportation costs. Keeping their customers’ safety in mind, VisiGuard® shields are manufactured in a cleanroom environment where operators are required to wear hairnets, face masks, and gloves and the parts are sealed inside of a plastic bag before being sealed in the box.

For more information on this product, give our team a call on 01634 686504.