At Sinclair & Rush, we have been committed to innovation and sustainability since 1950. Our latest offering, bio-based PVC Caps, Sleeves, and Grips, provides high-performance solutions for a variety of industries while actively reducing environmental impact.

What Are Bioplastics?

Bioplastics are materials derived from renewable biological sources such as plants, agricultural by-products, and organic waste. Unlike traditional plastics, which rely on fossil fuels, bioplastics use resources like lignocellulosic feedstock or organic waste, reducing dependency on non-renewable materials.

Not only are bioplastics more sustainable, but they can also be designed to match or exceed the performance of conventional plastics. They are increasingly used in industries seeking environmentally friendly alternatives without compromising on quality or durability.

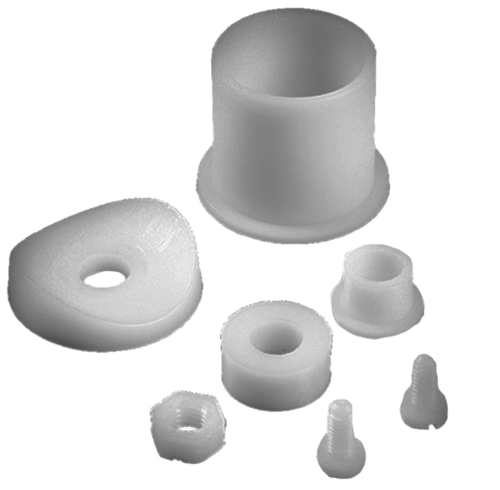

Flexible Bio-Based PVC Components for Modern Industries

Our bio-based PVC Caps, Sleeves, and Grips are crafted using bioplastics to deliver sustainable, high-performance solutions for industries such as automotive, aerospace, pharmaceutical, and hydraulics. These versatile components serve as protective coverings, masking solutions, or packaging aids, combining functionality with eco-conscious design.

Why Choose Sinclair & Rush Bio-Based PVC Components?

Eco-Friendly Materials

Our components are made using over 35% bio-based content derived from renewable sources. This shift away from fossil fuels helps businesses reduce their carbon footprint and support global sustainability goals.

High Performance

- Durability: Designed to withstand temperatures up to 130°C, our PVC components maintain their integrity in demanding conditions.

- Versatility: Suitable for a range of industrial applications, they provide excellent protection, insulation, and resistance to certain chemicals.

- Clean Finish: Their professional appearance enhances the overall quality of your products.

Environmental Impact

- Renewable Carbon Content: Our materials have over 17 times the renewable carbon content compared to traditional formulations.

- Reduced Carbon Footprint: By using components with a negative carbon dioxide equivalent, we help improve Global Warming Potential and lower greenhouse gas emissions.

- Phthalate-Free: Safer for users and better for the environment, our products avoid harmful additives commonly found in traditional plastics.

Applications at a Glance

Our PVC Caps, Sleeves, and Grips are ideal for:

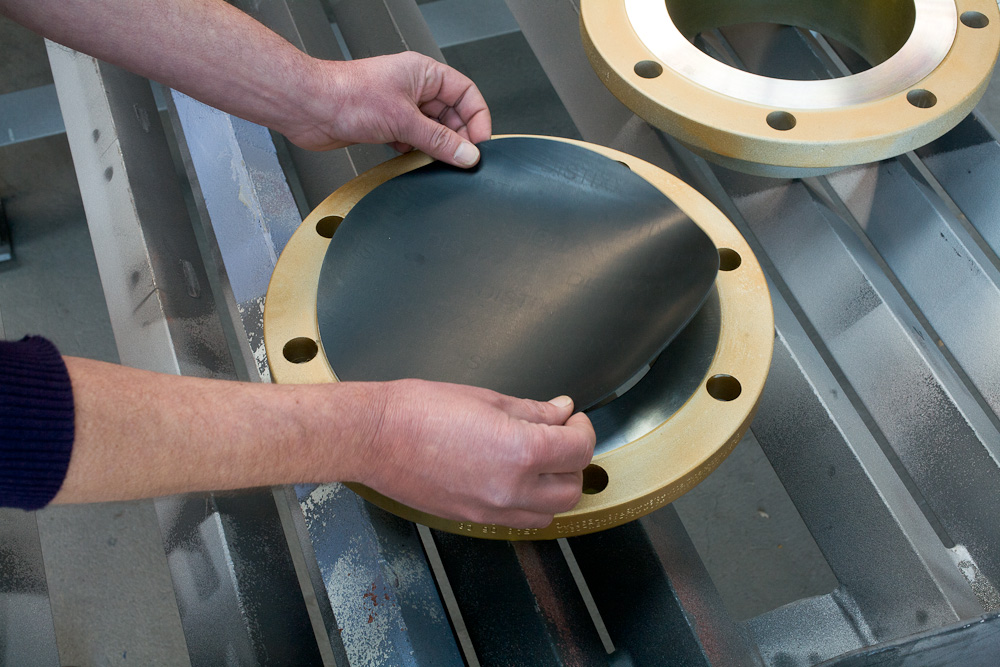

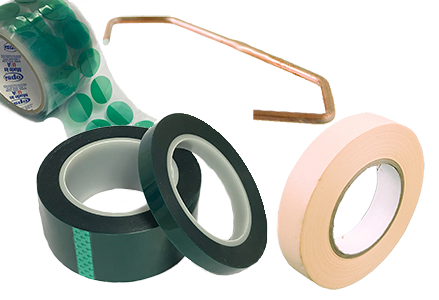

- Protecting components during transport or manufacturing

- Masking parts during finishing processes

- Safeguarding sensitive equipment or materials

- Providing durable covers for industrial tools and machinery

Technical Specifications

- Durometer Shore A: 60-70

- Maximum Operating Temperature: 130°C

- Elongation: 300%

- Tensile Strength: 15 MPa

These specifications ensure our products meet the highest standards of quality and reliability across industries. To view the Datasheet CLICK HERE

Why Bioplastics Matter

Bioplastics are part of a global effort to transition to a circular economy. By relying on renewable resources and reducing greenhouse gas emissions, they address critical environmental challenges such as plastic pollution and resource depletion. At Sinclair & Rush, we are proud to contribute to this movement by incorporating bioplastics into our product range.

A Greener Choice for Industrial Applications

Sinclair & Rush’s bio-based PVC Caps, Sleeves, and Grips offer an ideal balance of performance and sustainability. By choosing these components, you are reducing your environmental impact while benefiting from durable, high-quality solutions.

Ready to Make the Change?

Discover how Sinclair & Rush’s bio-based PVC Caps, Sleeves, and Grips can enhance your operations. Call us on 01634 684504 or email sales@sinclair-rush.co.uk to learn more.