In one of our previous articles, we touched on the difference between pre- and post-consumer recycled materials. But what does that really mean, and how does it affect recycling? Let’s take a closer look.

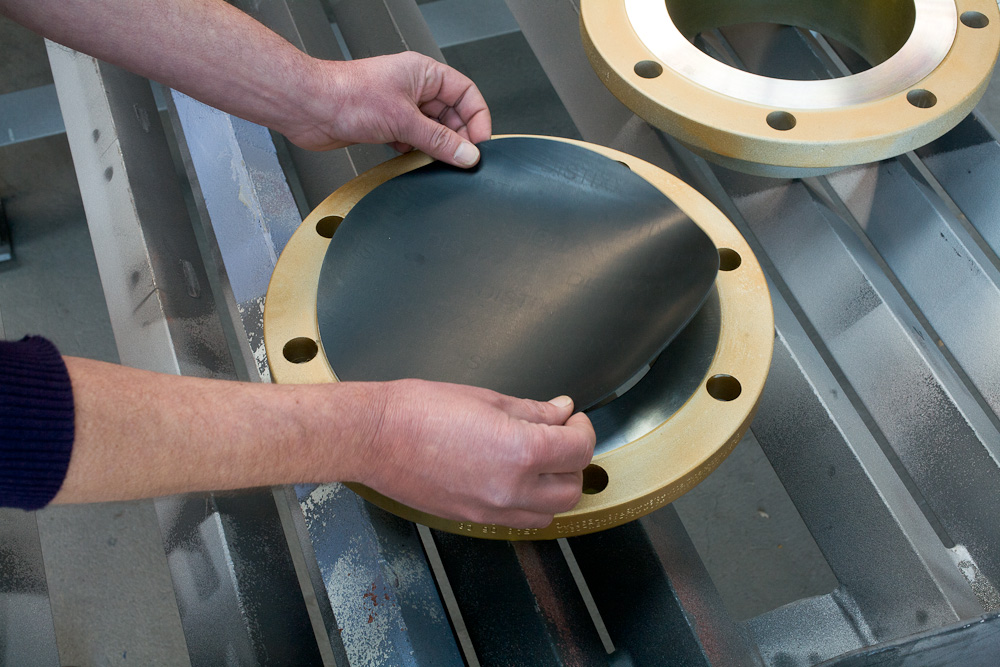

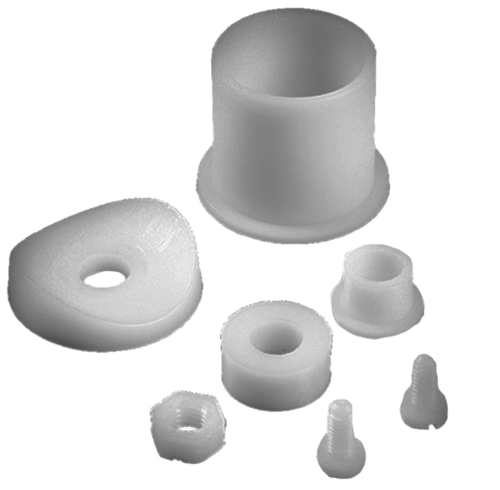

Pre-consumer materials, also called post-industrial recycling (PIR), refer to scrap materials that are recycled before they ever reach consumers. These are usually by-products of the manufacturing process, such as trimmings or defective parts. For instance, in plastic moulding, “runners” (the excess plastic from a mould) are cut away and recycled. This type of recycling is fairly straightforward, as the material is clean, unused, and easy to repurpose.

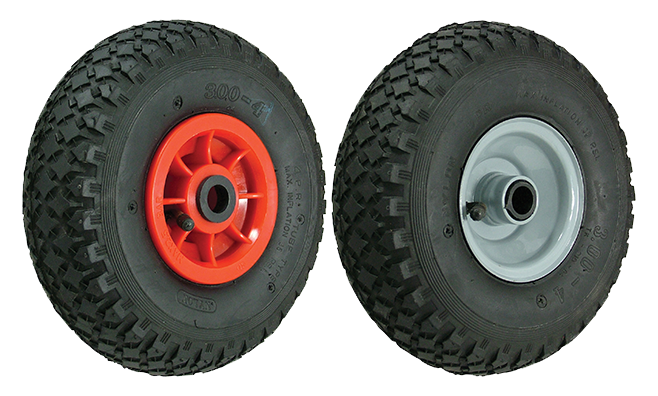

On the other hand, post-consumer materials (PCR) are items that have already been used and discarded by consumers, like the plastics you toss in your household recycling bin. Recycling these materials comes with greater environmental benefits, such as reducing landfill waste and cutting down on carbon emissions by avoiding the extraction of new petroleum. However, it also presents challenges. Post-consumer plastics can be contaminated, and each time plastic is recycled, it degrades in quality.

The Journey of Recycled Plastics

So, what happens to these materials once they enter the recycling stream? Let’s break it down:

- Pre-consumer recycling is efficient. Many manufacturers are able to reprocess these materials in-house or sell them to recycling companies, who turn them into reusable plastic resins. These resins are often high-quality and cost less to recycle than making new plastic from scratch.

- Post-consumer recycling, on the other hand, is more complex. After being collected, the items are sorted into different categories—plastic, glass, metal, paper—and undergo various processing stages. Plastics, in particular, need to be sorted by their chemical makeup, as different types of plastic degrade differently when recycled. After six or seven recycling cycles, the material is no longer viable.

The Challenges of Mixing Materials

Recycled plastics are often mixed with virgin materials to maintain quality standards, especially for products that require strength and durability. However, mixing can be tricky. If recycled plastic is too degraded, it can lead to defects in the final product, such as flashing, where excess material appears on the moulded product. This can damage manufacturing equipment and lead to additional costs for tooling maintenance.

There is also the option of using regrind—recycled plastic from multiple sources that has been processed into material of near-virgin quality. While this process is more sustainable and less energy-intensive than creating virgin plastics, it’s not without its complexities. As the Association of Plastic Recyclers explains, “recycled plastic is more energy-efficient than virgin plastic” because the process uses less energy than synthesising new plastic from raw chemicals.

The Impact of the Pandemic and Oil Prices

Before the pandemic, regrind plastics were often the more cost-effective option. But since 2020, fluctuating oil prices have caused the price of virgin plastics to drop, making them more appealing to manufacturers. This shift has decreased the demand for recycled content, posing a dilemma: should companies prioritise cheaper virgin plastics, or stick with recycled materials for the sake of sustainability?

It’s a tough decision for both businesses and consumers. Will people pay more for eco-friendly products? It’s a question that still lingers.

Post-Consumer Recycling: A Complex Process

Post-consumer recycling involves a more intricate process than its pre-consumer counterpart. Items like aluminium cans, newspapers, and plastic bottles are collected, shredded, and sorted by material. Metals are separated with magnets, while other materials go through ballistic sorting, optical sorting using infrared technology, and human checks for quality control.

Once sorted, these materials are sold to processors, who transform them into usable raw materials. While the system works, it has its inefficiencies and limitations. In the UK and beyond, there’s a need for better funding and infrastructure to improve recycling rates and handle waste on a larger scale.

What’s the Solution?

There’s no one-size-fits-all answer to improving recycling rates. Governments around the world need to come together, prioritise climate initiatives, and find a consolidated plan to encourage better recycling practices. Initiatives like chemical recycling and bioplastics are emerging, offering potential solutions. But until then, the responsibility lies with all of us to stay informed and make more sustainable choices.

We’re a long way from perfect, but if we all play our part, we can create meaningful change. In our next discussion, we’ll dive deeper into single use plastics.