At Sinclair & Rush, our Flexible PVC Caps are one of our most popular ranges; not to mention one of the oldest parts we have manufactured since the 1950s. Therefore we have become pioneers in the development of Dip Moulded products due to our vast experience. Over the years, we have improved our manufacturing methods and materials to ensure a top-quality product at a reasonable price.

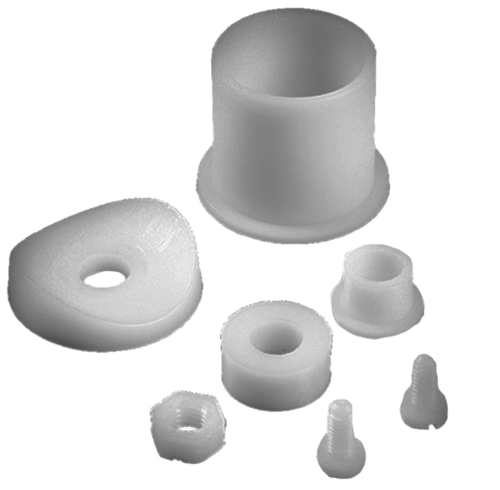

Within the Flexible Caps Range, as standard on the website, we do Round Caps and a range that are phthalate-free. We also do Square, Rectangle, Pole, Pull tab, Angle & Vinyl shaped Caps. As with all of our parts, they are multi-purpose but predominantly this range are used to close off, finish and protect open/ sharp ends or tubes. The Pull Tab Caps are commonly used for machinery or equipment to protect the Operator's hands, and we offer versions that can withstand high heat temperatures. With tools already set up for this range, we offer hundreds of sizes, shapes and styles to suit everyone's needs....

Ellie in our Marketing team has put together product review videos for each style so you can see a close-up of the item and understand their unique benefits. Take a look at the main one for Caps and simply scroll through our YouTube channel or the category page on the website for more!

So now for the technical stuff...

How do we make our Flexible PVC Caps?

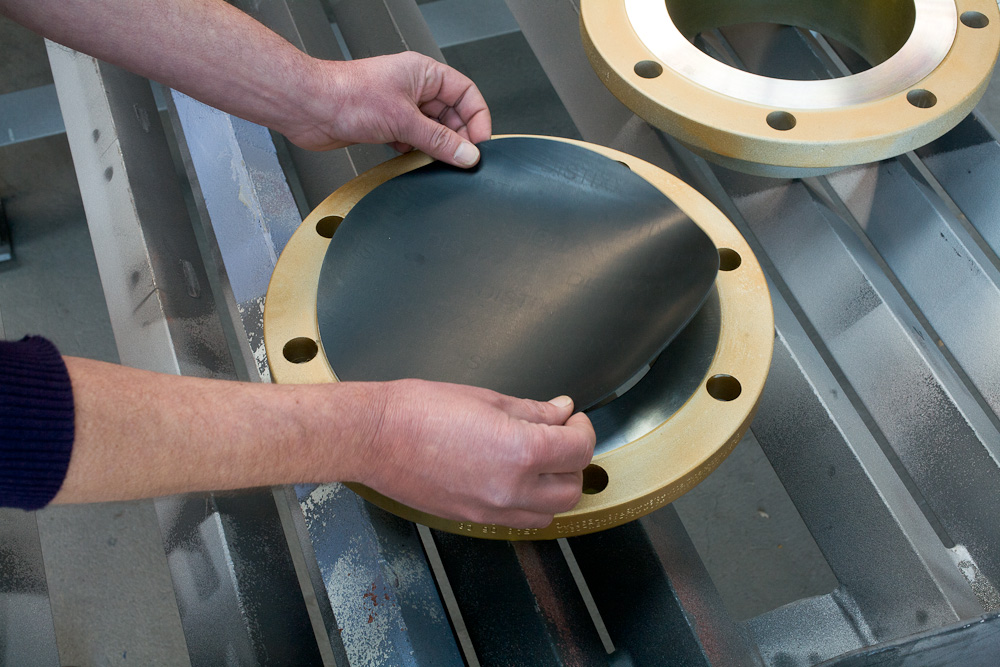

We manufacture our Caps using a process called Dip Moulding. Essentially this is where heated cylinders are dipped into liquid plastisol, before the coating is cured and then removed from the metal. We have a huge range of machinery depending on whether the work is low or high volume for long-dip jobs.

What are the benefits to Dip Moulding?

- Quick & inexpensive prototypes

- Option for Phthalate-free PVC material

- Forward-thinking materials and textures with outstanding colours available

- Flexible and durable products

- Attractive finish

- Low tooling costs

- Short lead times on custom orders

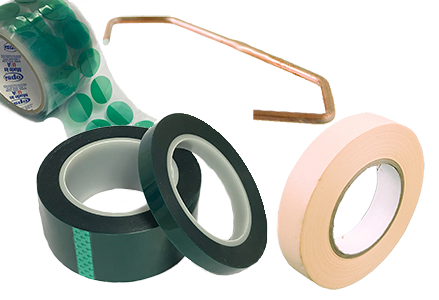

At our Rochester and Maidstone Kent Factories, we have a Secondary side to the business, all in-house, so we can finalise products with your unique touches in ways such as:

- Printing

- Double Trimming

- Punching

- Bagging

PVC Dip Moulded products provide flexibility and durability, coupled with low initial costs, making them a superior option for thousands of applications. Whether seeking an economical and cost-effective masking solution or a visually appealing finishing touch, our extensive selection of standard parts is an ideal starting point.

Click HERE to explore the full range.....