It’s surprising how many industries rely on castors and wheels to facilitate their day-to-day operations; they’re the unsung heroes of the working world. You’ll find castors and wheels in any number of environments, including warehouses, offices, hospitals, restaurants, and retail departments; they ensure that loads, such as deliveries and equipment, can be efficiently moved around the workplace by employees without much physical effort.

However, choosing the right sets of casters and wheels for each of these environments is not an easy task. There are a number of things to consider when distinguishing between product types, which could be the difference between having a solution that works effectively and one that could be detrimental to productivity – in many cases, choosing the wrong castors and/or wheels can prove very costly.

In this guide, we share everything you need to know about selecting the right castors and wheels for your needs.

Does It Really Matter Which Castors & Wheels You Choose?

Yes, it does! Here are just three ways the right (or wrong) castors can make a big impact on your business:

• Ease Of Use – The right castors and wheels can do wonders for day-to-day productivity; the easier the product is to use, the quicker tasks are completed. Likewise, the wrong castor can make moving loads extremely difficult, leaving workers feeling frustrated.

• Safety – Not only can bad castors make work slower, they can also make moving heavy loads quite dangerous. If a castor is too stiff, doesn’t swivel properly, or isn’t designed to adequately support the load, there is a risk of workers over-exerting themselves or even becoming injured if the load falls.

• Floor Protection – Heavy items can damage the floor when being moved if you don’t choose the right material for your wheels.

What To Consider When Choosing Castors & Wheels?

In order to avoid any of the above events, you need to make sure you’re choosing the right castors and wheels for your work environment. Here are some of the most important aspects to bear in mind:

• Wheel Diameter: Larger wheels make a load easier to move, so try to choose the largest wheels possible, without increasing your load’s centre of gravity; this can cause the load to tip when being moved.

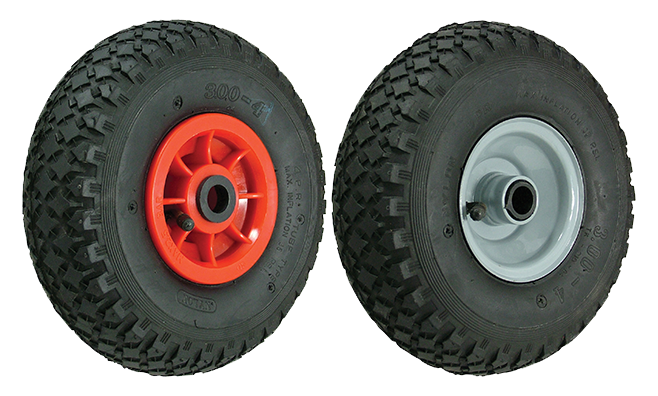

• Rollability: Different materials have different levels of rollability, so it’s important to consider what’s right for your load. Plastic wheels are easier to move, but they will also pick up momentum much faster – if you have a particularly heavy load, you want to ensure that workers will still have control if it’s moving at speed. Rubber wheels are harder to move, but they do offer a degree of control.

• Swivel Radius: You’ll need to decide whether you want a castor with swivel capacity. This would allow workers to navigate corners more easily, but would also require more control.

• Brakes: There are two main braking options to choose from: friction brakes and locks. A friction brake offers users more control over the speed of a load when transporting it; this might be useful in environments where loads are moved amongst the general public, like hospitals. Locks prevent the load from moving when left unsupervised.

• Load Capacity: Every castor is designed to support a maximum weight. It is crucial to stay within the maximum weight load so as not to cause damage to the castor itself. As a general rule, additional castors can increase the maximum load capacity of a cart or trolley.

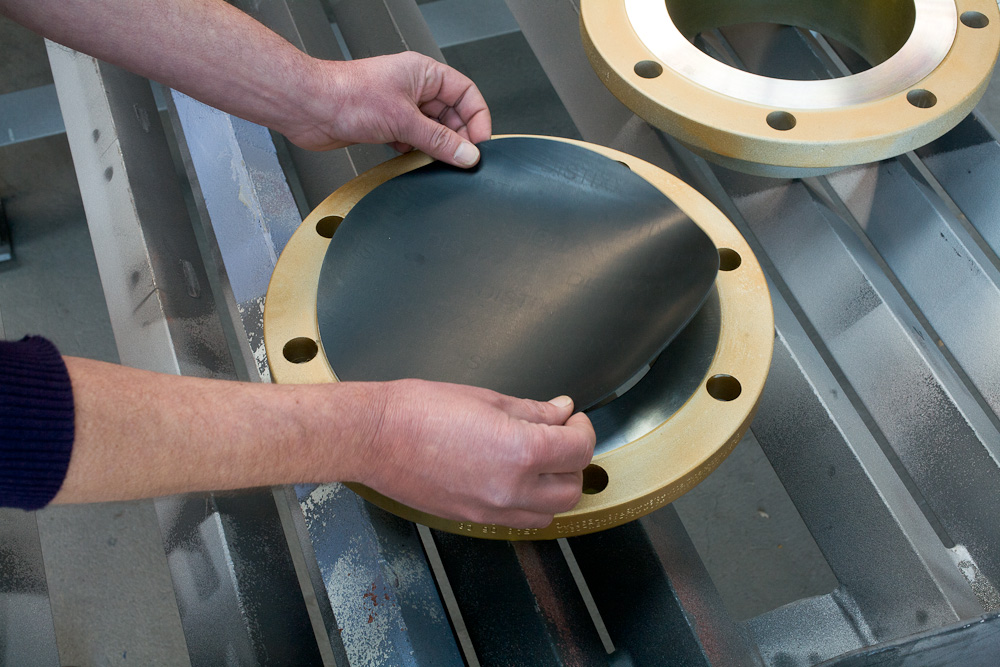

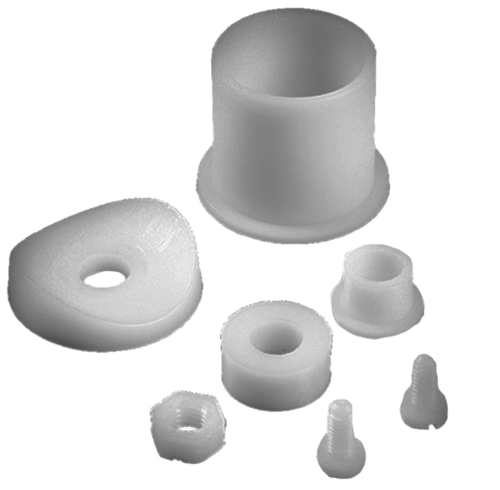

• Mounting: When mounting your castor, you can choose from two different options: top plates, which are attached to the cart or trolley surface using a bolt, and press threads (or screw threads) which are attached via an insert.

All of this can seem overwhelming if you’re not experienced in ordering castors and wheels. Luckily, our expert sales team are happy to learn more about your project and advise on the best solution for you. Get in touch today on 01634 686 504.