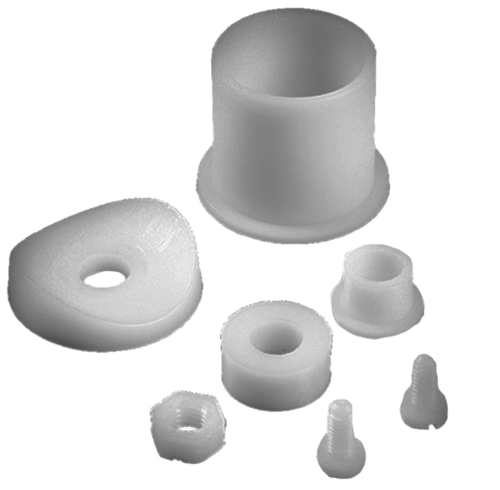

At Sinclair & Rush, sustainability is at the heart of everything we do. We’re excited to share that we’re trialling 100% recycled nut caps and inserts made entirely from our own manufacturing waste. This marks an important step forward in our commitment to reducing waste and embracing circular manufacturing practices.

Aiming for 100% Regrind Material

The focus of our trials has been on creating small parts, such as M10 and M12 nut caps, using 100% regrind material. Unlike conventional production, these trials allow us to fully utilize leftover scrap materials, such as LDPE (low-density polyethylene), and feed them directly back into the production process.

A key benefit of this approach is that the colour of the material doesn’t matter—it’s all about functionality. By introducing 100% regrind into the loader machine and adjusting the machine settings, we’ve been able to produce small, high-quality components.

The Challenges and Opportunities of Recycled Materials

Through the trials, we’ve observed some differences in the structure of the recycled parts. For instance, the components are slightly softer and lose a bit of structural rigidity compared to parts made from virgin material. To address this, we’re focusing on black items, which make the recycling process more efficient and allow us to better assess the results.

Over the years, we’ve worked tirelessly to refine our methods, ensuring that recycled material performs well under production conditions. One important aspect of this is grinding the scrap material into pellets that melt smoothly when reintroduced into the barrels. This step ensures that the material flows consistently and doesn’t block the machinery.

Inspired by Global Practices

Our efforts have also been inspired by a visit to Italy, where Mark observed manufacturers successfully using 100% recycled material in their production processes. These materials were comparable in quality to the parts we currently produce and sell.

Trial Results: A Promising Future

So far, we’ve conducted three separate trials on different small parts, focusing exclusively on black items. The results have been highly encouraging:

- Nut Caps: Produced using 100% recycled material with excellent performance.

- Small Inserts: Consistently high quality, even with softer material properties.

- Black Components: Proved to be a reliable choice for regrind trials.

We’re working closely with suppliers like Horizion, who provide regrind materials, and constantly refining our methods to ensure the best possible results.

Looking Ahead

Recycling sprues and other production waste into high-quality components is not just a cost-effective solution—it’s a crucial step towards a more sustainable future. At Sinclair & Rush, we’re committed to innovating and testing new ways to reduce our environmental impact while maintaining the high standards our customers expect.

As Paul puts it:

“It’s not just about the aesthetics. It’s about ensuring the structure and functionality meet the demands of our customers, without compromising sustainability.”

Stay tuned as we continue to explore the possibilities of 100% recycled materials in our products, moving closer to a greener future.

we also have:

Maximising Sustainability: Regrind Plastic Trials at Sinclair & Rush

At Sinclair & Rush, we are continuously striving to enhance sustainability by increasing the use of regrind materials in our products. Our latest trials focus on making as many items as possible from 100% regrind plastic, ensuring both efficiency and environmental responsibility.

Optimising Regrind for Small Parts Production

One of our key targets for regrind usage is nut caps, specifically M10 and M12 sizes, along with other small inserts. These parts are ideal for incorporating 100% regrind material, as they do not require specific colour consistency. By adjusting machine settings and production parameters, we have successfully manufactured nut caps using 100% regrind LDPE (Low-Density Polyethylene).

Challenges and Adjustments

While regrind material performs well in many applications, there are some differences compared to virgin plastic. For example, nut caps made with 100% regrind are slightly softer and may lose a small amount of structural integrity. However, our trials indicate that the differences are minimal and do not affect the function of the product.

To ensure high-quality production, our process involves:

- Feeding regrind material directly into the loader machine.

- Adjusting machine settings for optimal melting and flow.

- Conducting multiple trials on different parts to assess strength and consistency.

Global Insights and Industry Comparisons

Earlier this year, our team visited manufacturers in Italy, where it was confirmed that some companies already use 100% recycled material in their machines. This aligns with our sustainability goals and reassures us that our trials are on the right path.

So far, we have conducted three different trials on three different parts, including nut caps and small inserts—each yielding positive results. These efforts help reduce waste and enhance our contribution to the circular economy.

The Role of Regrind and Processing Techniques

Regrind plastic typically comes from scrap material, such as sprues, which need to be finely ground before being reintroduced into the production process. The key challenge is ensuring that the regrind melts properly within the barrels, preventing blockages and maintaining smooth flow. To achieve this, the plastic must be ground into pellets of the correct size.

Paul [Last Name/Title] commented:

“We’ve been trialling regrind materials for years. While some applications require further refinement, these trials prove that for small parts like nut caps, 100% regrind is a viable and sustainable solution.”

Next Steps in Our Sustainability Commitment

Our current focus is on black-coloured parts, as colour uniformity is less critical in these applications. By continuing to refine our processes and expand our regrind usage, we aim to manufacture more of our products using 100% recycled materials without compromising performance.

We are proud of our progress and will keep testing and innovating to reduce our environmental footprint. Stay tuned for more updates on our sustainability journey!