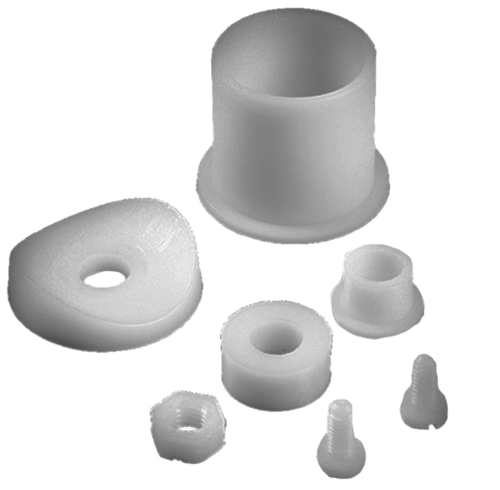

At the end of last year, Sinclair & Rush acquired 8 new injection moulding machines which have since been moved into main production centre in Rochester. And with new machines brings new capabilities!

The addition of these new machines means that we can now run larger tools, and therefore produce larger items. We can also run small items in larger tools for more impressions per cycle! This all means that high-volume jobs can be produced more quickly and efficiently, resulting in a better service for our valued customers.

Let’s meet the fleet!

The Billions are an exciting new addition to our factory, and we can’t wait to start using them. Each of the 5 machines has a different volume, increasing our capacity for larger and smaller products. Here’s how they measure up:

Billion: Proxima H430/80 – 80Ton

• Clamping Force: 800kN

• Max Shot Volume: 293cc (266g PS)

• Tool Height Range: 200-400mm

• Best suited for: Small plugs/Caps

• Low to Medium Volume production runs of small parts. Quick and easy running with fast tool change times!

Billion: Hercule H470/90 – 90 Ton

• Clamping Force: 900kN

• Max Shot Volume: 278CC (255g PS)

• Tool Height Range: 180-400mm

• Best suited for: Small caps and inserts.

• Low to medium volume production runs of small parts. Versatile and flexible!

Billion: Hercule H780/140 Ton

• Clamping Force: 1368kN

• Max Shot Volume: 422cc (384g PS)

• Tool Height Range: 180-480mm

• Best suited for: medium to large Caps / Grips.

• Medium to High volume production runs of larger parts than the Hercule 80/90. A reliable and adaptable machine, a good all-rounder!

Billion: Hercule H780/200 - 200Ton

• Clamping Force: 2010kN

• Max Shot Volume: 422cc (384g PS)

• Tool Height Range: 280-580mm

• Best suited for: Large pipe caps, inserts and grips.

• High volume production of medium to large parts or high cavity count tool for mass production of smaller components. There’s not much this machine can’t do!

Billion: Hercule H2000/320Ton

• Clamping Force: 3200kN

• Max Shot Volume: 1097cc (998g PS)

• Tool Height Range:330-680mm

• Best suited for: Large moulds – very high volume larger caps and inserts.

• Large parts a speciality! With a shot volume of nearly 1kg this is our biggest machine yet! A substantial and reliable machine!

BOY 35E - 35 Ton

• Clamping Force: 350kN

• Max Shot Weight: 43g

• Possible tool size: 210x210mm

• Best suited for: Small Caps & Plugs

• Low to Medium Volume production runs of small parts. Smooth running with quick tool changes! Responds easily to ever changing customer demands!

BOY 50M – 50Ton

• Clamping Force: 500kN

• Max Shot Weight: 62g

• Possible tool size: 210c210mm

• Best suited for: Small caps and plugs

• Small to medium production runs of small parts.

• Reliable and dependable!

BOY 55E – 55Ton

• Clamping Force: 550kN

• Max Shot Weight: 71g

• Possible tool size: 280x280mm

• Best suited for: Small caps & Inserts

• Small to medium production of small components.

• Quick and easy tool changes meaning fast response times for the customer!

BOY 90Mse – 90Ton

We have a range of BOY machines and we’re very familiar with their capabilities. This machine is one of our most responsive:

• Clamping Force: 900kN

• Max Shot Weight: 142g

• Possible tool size: 210x350mm

• Best suited for: Inserts.

• Medium to large volume runs of smaller components. This robust and responsive machine can handle most of today’s demands easily!

Arburg 470C – 150Ton

• Clamping Force: 1500kN

• Max Shot Weight: 184g

• Possible tool size: 420x490mm

• Best suited for: Medium sized Inserts, caps & plugs

• A no nonsense and ultra-reliable machine, especially for medium to high volume production. It really is a fantastic ‘All-rounder’!