As a Plastics Manufacturer, we have several methods available to make our parts. In most cases, this depends on the materials being used, the quality and accuracy required, the aesthetics and feel of the finished article and, the volume and production speed needed to satisfy the customer’s demand.

There are many plastic manufacturing methods ( 6+) but today we are going to briefly look at the most common ones in the industry, and the ones in use at Sinclair & Rush in the UK, USA, Australia and China.

Plastic Extrusion

The process of pushing heated material through a die to create a continuous profile, such as a tube. Using a combination of central pins and vacuum chambers, a multitude of shapes can be achieved. Once cooled, this profile is then cut to specified lengths on the line.

We introduced this method to our UK Factory in 2016 to meet the needs of our UK & European customers. We are now producing tube products locally, that had been, for many years, imported from our US facility.

Extrusion is an extremely economical & efficient manufacturing option producing minimal material waste. Products can be made very quickly and high-volume demands met.

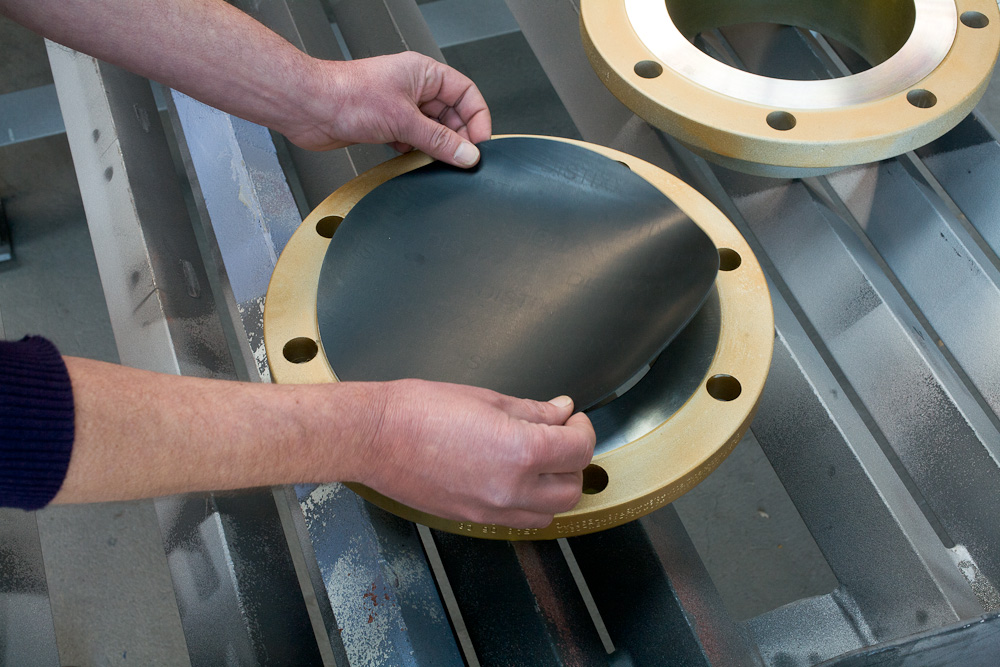

Vinyl-Dip Moulding

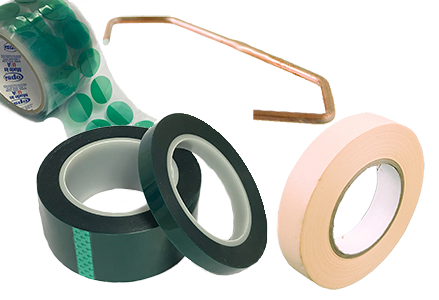

A process in which heated mandrels are dipped into liquid plastisol (PVC). The ‘liquid PVC’ solidifies on contact with the hot tools, before the coating is then oven-cured and finally stripped from the metal formers.

Our fleet of machinery in the UK ranges from small single-dip batching rigs for low-volume work and rapid prototyping, to high-volume machines with long-dip capabilities.

PVC Dip Moulded products are flexible and durable along with low set-up costs, making them an excellent choice for thousands of applications.

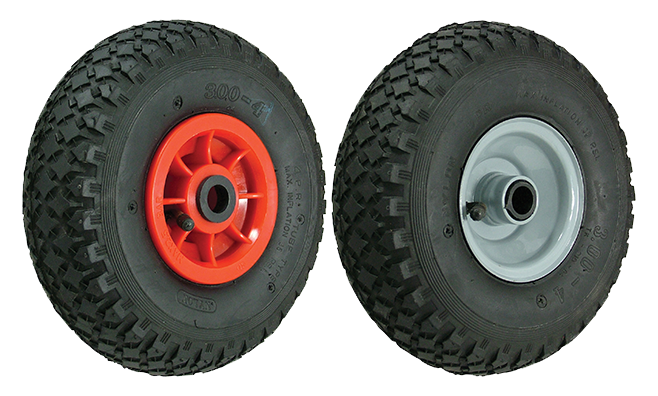

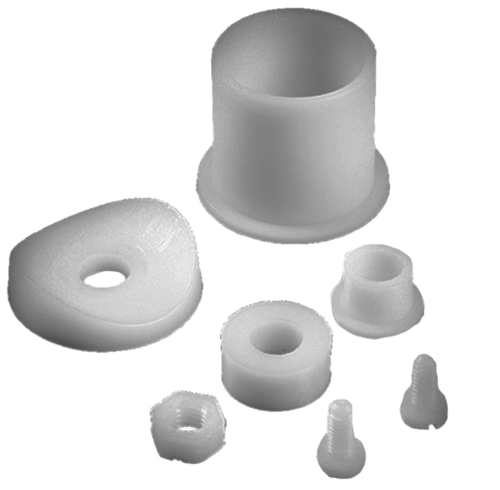

Injection Moulding

An extremely reliable and self-sufficient process in which different types of plastic granules are heated until ‘fluid’ and then ‘injected’ into metal moulds at high pressure. This hot plastic fills the mould cavities and will retain that form once cooled.

This is a more accurate and controllable process, as modern injection moulding machines are full of technology used to recreate perfect results over and over again. Whilst the initial tooling set-up is more expensive, a much higher level of precision is achievable.

Thermoforming

Thermoforming is a process of heating thermoplastic sheeting and placing it over a mould or former until cooled. In its thin gauge form, its primary forms are extensively used to produce disposable packaging for retail applications such as salad boxes. Whereas the thicker gauge form is used to mould everything from shipping trays to facias in automobiles and interior components in refrigerators.

Foam Extrusion

The foam extrusion process is similar in nature to most other extrusion processes in that a rubber compound is mixed with foaming agents, pushed through dies, and then cured and cooled for packaging or further processing.

Secondary processing often involves the use of high-speed grinding equipment that shapes the tubes or rounds off the edges for a more attractive appearance.

S&R USA uses this process to make many of the tubular foam grips that you will find on our website.

I hope this article has given you some more insight into the more common methods of Plastic Manufacturing.

To browse our products, just head to the category section of our website.