Being in the Plastics Business, it is important for us, more than most, to actively look at our processes and procedures, regularly, to ensure they are as economical as possible. We aim to deliver the quality of products our customers need but in the most environmentally friendly way.

This article is essentially a refresher of previous articles to remind our customers that waste management is still a vital part of our business model.

As part of our global environmental responsibility, each branch and factory at Sinclair & Rush carries out different methods to support the environment. Being a manufacturer of raw materials and plastic, we do have some non-recyclable waste but we strive to re-use as much as possible.

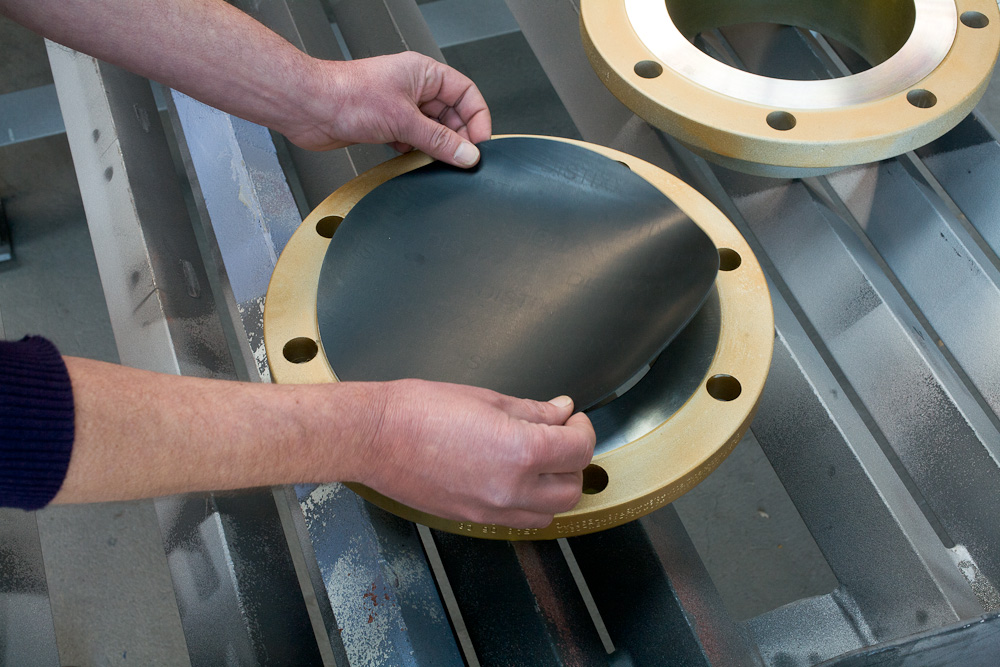

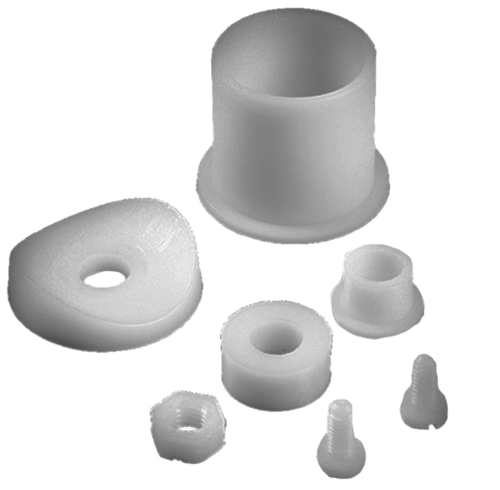

Something we do want to "shout about" is at Sinclair & Rush UK, we work with James - MD at Horizon Polymers. Horizon buys our plastic waste such as PVC, Nylon or LDPE and grinds it down into pellets and sells it to other UK-based Manufacturers who make their products with it. Items include hazmat boots, safety cones even playground surfacing. We are very proud of this partnership due to the incredible benefits to the environment.

Furthermore, here is a list, of all of the day-to-day environmental practices we carry out. This is being reviewed constantly...

- Constant analysis of raw materials used in production to meet regulations including ISO.

- Use of recyclable materials in the production of final consumer packaging.

- We have dedicated staff that put their heads together regularly to discuss how to be greener, our "Eco Team"

- As much as possible all invoices and receipts are email copies so not to use unnecessary amounts of paper.

- We have kept remote working for some office staff (if the role suits) which has dramatically reduced running costs such as electric bills and paper usage for example, which in turn has helped the environment.

- For those in the office and factory still, we have shred-it bins throughout the buildings, which when full, are returned and recycled by the companies who collect them.

- We have a Return & Recycle Scheme within schools. This means the schools send us their worn chair feet for free and we recycle them to help manage the global waste problem.

- All bulbs have been replaced with energy-efficient ones.

- Cardboard is collected in the factory and warehouse and periodically recycled.

- Expansion of raw materials offered to give customers more options.

- 99% of PETG is recycled in-house.

- Injection moulded components are ground down and sold on for upcycling.

- Other waste is sorted by ISO-compliant companies.

- Hazardous waste is managed by reputable companies.

- Energy usage is monitored within the company, with constant efforts to reduce where possible.

- We source our electricity and gas supply from renewable energy companies.

- Packaging supplies from external sources are reused where possible

- We have multiple other waste streams outside of raw materials that will be recycled

- WEEE waste (electrical equipment)

- Batteries

- Aerosol cans

- Fluorescent tubes

- Ink cartridges

From this refresher article, you can see that preserving the planet as much as possible is a priority for us at Sinclair & Rush. Also, we are in other discussions with businesses about more economical ways to manufacture our products so keep a look out on the news section of our website in the coming months!